- The potential hazards of laser cleaning technology

- Safety protocols and guidelines for using laser cleaning equipment

- The importance of proper training for operators of laser cleaning machines

- The risks associated with exposure to laser beams during the cleaning process

- The role of protective gear in ensuring the safety of workers using laser cleaning technology

The potential hazards of laser cleaning technology

Types of hazards

There are several types of hazards associated with laser cleaning technology, including:

| Hazard | Description |

|---|---|

| Eye hazards | Laser beams can cause permanent eye damage if proper eye protection is not worn. |

| Skin hazards | Direct exposure to laser beams can cause burns and skin damage. |

| Fire hazards | Laser beams can ignite flammable materials, leading to fires. |

| Toxic fumes | The process of laser cleaning can produce toxic fumes and gases that can be harmful if inhaled. |

Safety measures

To mitigate the risks associated with laser cleaning technology, it is important to implement the following safety measures:

| Safety measure | Description |

|---|---|

| Use proper eye protection | Always wear laser safety goggles that are designed to protect against the specific wavelength of the laser beam being used. |

| Wear appropriate clothing | Wear long sleeves and pants made of non-flammable materials to protect your skin from laser beams. |

| Ensure proper ventilation | Use exhaust systems to remove toxic fumes and gases from the work area. |

| Follow safety guidelines | Adhere to the manufacturer’s safety guidelines and receive proper training on the use of laser cleaning technology. |

Conclusion

While laser cleaning technology offers many benefits, it is important to be aware of the potential hazards associated with its use. By implementing proper safety measures and following guidelines, users can minimize the risks and ensure a safe working environment.

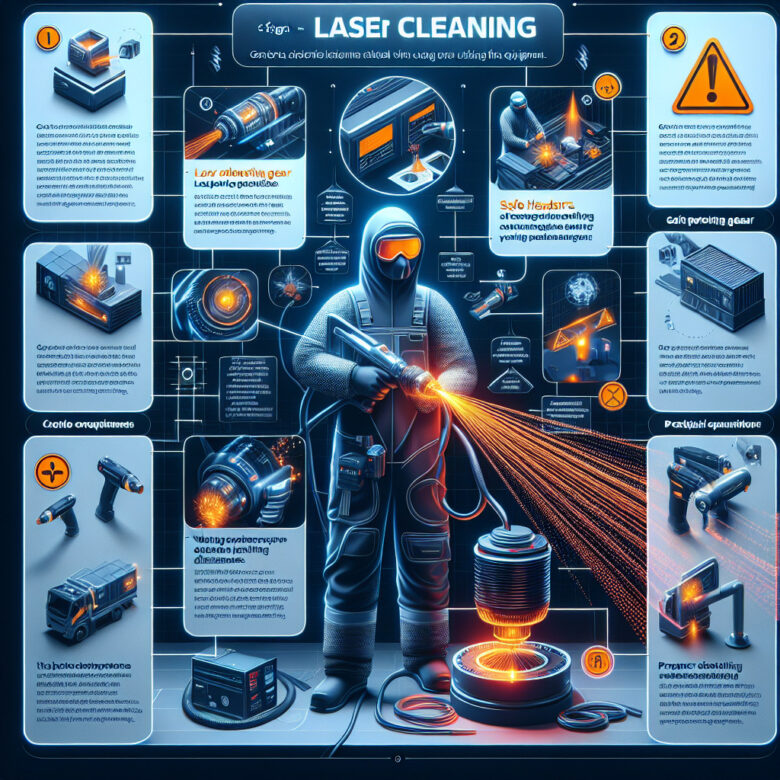

Safety protocols and guidelines for using laser cleaning equipment

- Wear appropriate protective gear: When using laser cleaning equipment, it is important to wear the proper protective gear to protect yourself from potential hazards. This may include safety goggles, gloves, and a face shield.

- Ensure proper training: Before using laser cleaning equipment, make sure that you have received proper training on how to operate the equipment safely. This will help prevent accidents and injuries.

- Inspect the equipment: Before using laser cleaning equipment, inspect it for any damage or defects. Do not use the equipment if it is not in proper working condition.

- Follow manufacturer’s instructions: Always follow the manufacturer’s instructions for operating the laser cleaning equipment. This will help ensure that you are using the equipment safely and effectively.

- Keep a safe distance: When using laser cleaning equipment, make sure to keep a safe distance from the surface being cleaned to prevent accidental exposure to the laser beam.

- Avoid reflective surfaces: Do not use laser cleaning equipment on reflective surfaces, as this can cause the laser beam to bounce back and potentially cause harm.

- Use proper ventilation: Make sure that the area where you are using laser cleaning equipment is well-ventilated to prevent the buildup of fumes and vapors.

- Do not point the laser beam at people: Avoid pointing the laser beam at people or animals, as this can cause serious injury.

- Turn off the equipment when not in use: When you are not using laser cleaning equipment, make sure to turn it off and unplug it to prevent accidental activation.

- Dispose of waste properly: Dispose of any waste generated by the laser cleaning process properly, following all local regulations and guidelines.

By following these safety protocols and guidelines, you can help ensure that you are using laser cleaning equipment safely and effectively. Remember to always prioritize safety when using any type of equipment, and do not hesitate to seek help or guidance if you are unsure about how to use the equipment properly.

The importance of proper training for operators of laser cleaning machines

Proper training is essential for operators of laser cleaning machines for several reasons:

- Safety: Laser cleaning machines use high-powered lasers that can cause serious injury if not handled properly. Operators must be trained on how to safely operate the machine, including wearing appropriate protective gear and following safety protocols.

- Efficiency: Proper training can help operators maximize the efficiency of the laser cleaning process. By understanding how to adjust the settings and position the laser correctly, operators can ensure that the machine effectively removes contaminants from the surface.

- Maintenance: Operators who are properly trained can also help prevent damage to the machine. By understanding how to properly maintain and calibrate the laser cleaning machine, operators can prolong its lifespan and reduce the need for costly repairs.

- Quality: Finally, proper training can help operators achieve high-quality results. By learning how to properly clean different types of surfaces and adjust the laser settings accordingly, operators can ensure that the finished product meets the desired standards.

Overall, proper training for operators of laser cleaning machines is crucial for ensuring safety, efficiency, maintenance, and quality.

Operators who are properly trained can not only protect themselves and others from harm but also maximize the effectiveness of the machine and produce high-quality results.

Therefore, it is important for companies that use laser cleaning machines to invest in training programs for their operators to ensure that they have the knowledge and skills necessary to operate the machines safely and effectively.

The risks associated with exposure to laser beams during the cleaning process

Types of laser beams

There are different types of laser beams used in cleaning processes, including:

| Type | Description |

|---|---|

| CO2 lasers | These lasers are commonly used for cleaning applications due to their high power and efficiency. |

| Fiber lasers | These lasers are known for their precision and are often used for delicate cleaning tasks. |

| YAG lasers | These lasers are versatile and can be used for a wide range of cleaning applications. |

Risks of exposure to laser beams

Exposure to laser beams during the cleaning process can pose several risks, including:

| Risk | Description |

|---|---|

| Eye injuries | Direct exposure to laser beams can cause damage to the eyes, leading to vision problems or even blindness. |

| Skin burns | Laser beams can also cause burns to the skin if proper protective gear is not worn during the cleaning process. |

| Inhalation of fumes | Some cleaning processes may produce fumes that can be harmful if inhaled, leading to respiratory issues. |

Preventing risks during laser cleaning

To prevent the risks associated with exposure to laser beams during the cleaning process, it is important to follow safety guidelines, including:

- Wearing appropriate protective gear, such as safety goggles and gloves, to protect against eye injuries and skin burns.

- Ensuring proper ventilation in the cleaning area to prevent the inhalation of harmful fumes.

- Training employees on the safe use of laser cleaning equipment and procedures.

- Regularly inspecting and maintaining laser cleaning equipment to ensure it is in good working condition.

Conclusion

While laser cleaning is a valuable tool for removing contaminants from surfaces, it is important to be aware of the risks associated with exposure to laser beams during the cleaning process. By following safety guidelines and taking proper precautions, these risks can be minimized, ensuring a safe and effective cleaning process.

The role of protective gear in ensuring the safety of workers using laser cleaning technology

The dangers of laser cleaning technology

When using laser cleaning technology, workers are exposed to several potential hazards. The intense light and heat generated by the laser can cause eye damage, skin burns, and respiratory issues if proper precautions are not taken. In addition, the process of laser cleaning can produce hazardous fumes and particles that can pose a risk to workers’ health.

The importance of protective gear

Protective gear plays a crucial role in minimizing the risks associated with laser cleaning technology. By wearing the appropriate gear, workers can protect themselves from the harmful effects of the laser and ensure their safety while performing their tasks.

- Eye protection: One of the most important pieces of protective gear for workers using laser cleaning technology is eye protection. Laser light can cause permanent damage to the eyes, so it is essential for workers to wear safety goggles or glasses that are specifically designed to block out the harmful wavelengths of light produced by the laser.

- Skin protection: In addition to eye protection, workers should also wear protective clothing to shield their skin from the heat generated by the laser. This may include flame-resistant coveralls, gloves, and aprons made from materials that can withstand high temperatures.

- Respiratory protection: To protect against the inhalation of hazardous fumes and particles produced during the laser cleaning process, workers should wear respiratory protection such as masks or respirators. This will help prevent respiratory issues and ensure the safety of workers’ lungs.

Training and education

Aside from wearing protective gear, it is also important for workers to receive proper training and education on the safe use of laser cleaning technology. This includes understanding the potential hazards associated with the technology, knowing how to operate the equipment safely, and being aware of emergency procedures in case of accidents or injuries.

Regular maintenance and inspections

Furthermore, regular maintenance and inspections of the laser cleaning equipment are essential to ensure that it is functioning properly and safely. This includes checking for any signs of wear or damage, replacing worn-out parts, and conducting routine inspections to identify any potential hazards that may arise during operation.

Conclusion

In conclusion, protective gear plays a vital role in ensuring the safety of workers using laser cleaning technology. By wearing the appropriate gear, receiving proper training, and conducting regular maintenance and inspections, workers can minimize the risks associated with laser cleaning and protect themselves from harm. It is essential for employers to prioritize the safety of their workers and provide them with the necessary tools and knowledge to work safely with laser cleaning technology.

- The safety considerations of laser cleaning - 17 July 2024

- Applications of laser cleaning in the automotive industry - 12 April 2024