- Introduction to laser cleaning technology

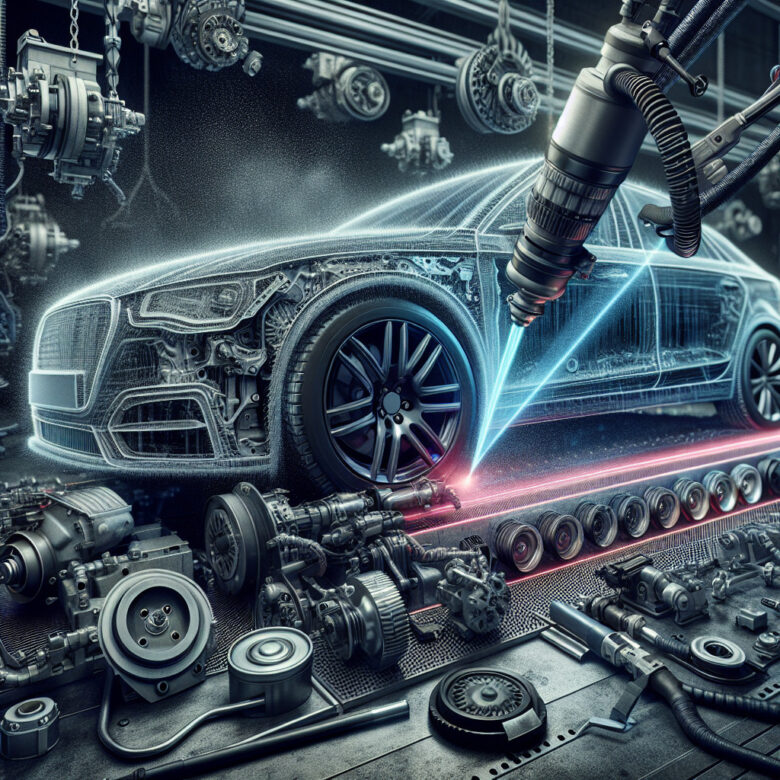

- Applications of laser cleaning in paint removal

- Laser cleaning for adhesive removal

- Laser cleaning for aluminum and other metals

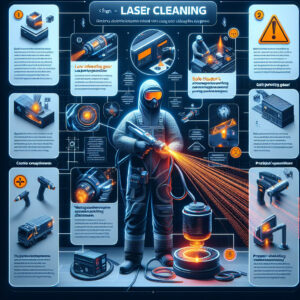

- Safety considerations for laser cleaning in automotive applications

- Future trends in laser cleaning technology for the automotive industry

- Impact of laser cleaning on overall product quality

- Impact of laser cleaning on overall manufacturing costs

Introduction to laser cleaning technology

How Laser Cleaning Works

The laser cleaning process involves focusing a laser beam on the surface to be cleaned. The energy from the laser beam vaporizes the contaminants, coatings, or oxides on the surface, leaving behind a clean and residue-free surface. The laser beam can be adjusted in terms of power, intensity, and duration to suit different cleaning requirements. Laser cleaning is a non-contact and non-abrasive method, making it ideal for delicate surfaces.

Benefits of Laser Cleaning Technology

| Benefits | Description |

|---|---|

| 1. Precision | Laser cleaning allows for precise control over the cleaning process, ensuring consistent results. |

| 2. Efficiency | Laser cleaning is faster and more efficient than traditional cleaning methods, reducing downtime. |

| 3. Environmentally friendly | Laser cleaning does not require the use of chemicals or abrasive materials, making it eco-friendly. |

| 4. Versatility | Laser cleaning can be used on a wide range of materials and surfaces without causing damage. |

Applications of Laser Cleaning Technology

Laser cleaning technology is used in various industries for different applications, including:

| Industry | Application |

|---|---|

| Automotive | Removing paint and rust from car bodies. |

| Aerospace | Cleaning turbine blades and engine components. |

| Electronics | Removing solder and flux residues from circuit boards. |

| Cultural Heritage Preservation | Cleaning delicate artifacts and sculptures without causing damage. |

Conclusion

Laser cleaning technology is a cutting-edge method of surface cleaning that offers numerous benefits over traditional cleaning methods. Its precision, efficiency, and environmental friendliness make it a preferred choice for industries looking to improve their cleaning processes. With its wide range of applications, laser cleaning technology is set to revolutionize the way surfaces are cleaned in various industries.

#laser #cleaning #technology #precision #efficiency #environmentallyfriendly #versatility #automotive #aerospace #electronics #culturalheritagepreservation

frazy kluczowe:

– advanced laser cleaning technology

– benefits of laser cleaning

– laser cleaning applications

– laser cleaning process

– laser cleaning equipment

– laser cleaning advantages

– laser cleaning industry trends

– laser cleaning market analysis

– laser cleaning future prospects

– laser cleaning challenges and solutions

Applications of laser cleaning in paint removal

1. Automotive industry 🚗

Laser cleaning is commonly used in the automotive industry to remove paint from cars, trucks, and other vehicles. This method is preferred over traditional sandblasting or chemical stripping because it is faster, more precise, and environmentally friendly.

2. Aerospace industry ✈️

In the aerospace industry, laser cleaning is used to remove paint from aircraft components such as wings, fuselages, and engine parts. This technology ensures that the underlying metal is not damaged during the paint removal process, which is crucial for maintaining the structural integrity of the aircraft.

3. Historical preservation 🏛️

Laser cleaning is also used in the restoration of historical buildings, monuments, and artifacts. This method allows conservators to remove layers of paint without causing any damage to the original surface. It is particularly useful for delicate materials such as stone, wood, and metal.

4. Electronics manufacturing 📱

In the electronics manufacturing industry, laser cleaning is used to remove paint from circuit boards, components, and other electronic devices. This method ensures that the surfaces are clean and free of contaminants, which is essential for the proper functioning of the equipment.

5. Marine industry ⛵

Laser cleaning is increasingly being used in the marine industry to remove paint from ships, boats, and offshore structures. This method is particularly effective for removing anti-fouling coatings and marine paints without causing any damage to the underlying metal.

Overall, laser cleaning offers a wide range of applications in paint removal across various industries. Its ability to remove paint quickly, efficiently, and without damaging the underlying material makes it a valuable tool for many different applications.

#laser #cleaning #paintremoval #automotive #aerospace #historicalpreservation #electronicsmanufacturing #marineindustry

frazy kluczowe:

– Advanced technology for precise paint removal

– Environmentally friendly paint stripping method

– Preservation of historical artifacts with laser cleaning

– Efficient and effective paint removal in the automotive industry

Laser cleaning for adhesive removal

How does laser cleaning work?

Laser cleaning works by using a high-energy laser beam to heat and vaporize the adhesive residue on the surface. The intense heat causes the adhesive to break down and evaporate, leaving behind a clean and residue-free surface. The process is non-abrasive and does not require any chemicals, making it an environmentally friendly and safe method for adhesive removal.

Benefits of

- Fast and efficient

- Non-contact and non-abrasive

- Environmentally friendly

- Safe for delicate surfaces

- No chemicals or solvents required

Overall, laser cleaning is a versatile and effective method for removing adhesives from a variety of surfaces, including metal, plastic, glass, and ceramics. Whether you are dealing with residue from stickers, labels, or tape, laser cleaning can provide a quick and easy solution for restoring surfaces to their original condition.

Conclusion

When it comes to adhesive removal, laser cleaning offers a superior alternative to traditional methods. Its speed, efficiency, and non-contact nature make it an ideal choice for a wide range of applications. Say goodbye to messy solvents and tedious scraping – with laser cleaning, adhesive removal has never been easier!

#laser #cleaning #adhesive #removal

Keywords: laser cleaning, adhesive removal, non-contact, efficient, environmentally friendly

Long-tail phrases: laser cleaning for stubborn adhesive removal, non-abrasive method for removing adhesives, fast and efficient adhesive removal with laser technology.

Laser cleaning for aluminum and other metals

Benefits of laser cleaning:

– Non-abrasive: Laser cleaning does not require any abrasive materials, reducing the risk of surface damage.

– Environmentally friendly: Unlike traditional cleaning methods that use chemicals or abrasive materials, laser cleaning produces no waste or harmful byproducts.

– Precision: Laser cleaning can be controlled with high precision, allowing for selective removal of contaminants without affecting the underlying material.

– Efficiency: Laser cleaning is a fast and efficient process, making it ideal for industrial applications.

Applications of laser cleaning:

– Removing paint and coatings from metal surfaces

– Preparing surfaces for welding or bonding

– Cleaning molds and tooling in manufacturing processes

– Restoring historical artifacts and monuments

Overall, laser cleaning offers a versatile and effective solution for cleaning aluminum and other metals. Its non-contact nature and precision make it a preferred method for industries looking to improve efficiency and reduce environmental impact.

#laser #cleaning #aluminum #metals

Keywords: laser cleaning, aluminum, metals, surface preparation, industrial applications

Long-tail phrases: laser cleaning for aluminum surfaces, environmentally friendly metal cleaning, precision cleaning with lasers.

Safety considerations for laser cleaning in automotive applications

1. Eye protection: Laser beams can cause serious eye damage if proper precautions are not taken. It is essential to wear appropriate eye protection, such as laser safety goggles, when operating a laser cleaning system.

2. Fire hazards: Laser cleaning can generate a significant amount of heat, which can pose a fire hazard if not properly controlled. It is important to ensure that the work area is clear of flammable materials and that the laser system is equipped with appropriate safety features to prevent overheating.

3. Exhaust ventilation: Laser cleaning can produce fumes and particles that may be harmful if inhaled. It is important to have adequate exhaust ventilation in place to remove these contaminants from the work area and protect the health of operators.

4. Electrical safety: Laser cleaning systems require a significant amount of electrical power to operate. It is important to follow proper electrical safety procedures to prevent electrical shocks or other hazards.

5. Training and supervision: Proper training and supervision are essential for safe operation of a laser cleaning system. Operators should be trained in the use of the equipment and should be supervised by experienced personnel to ensure that safety protocols are followed.

In conclusion, laser cleaning can be a highly effective method for removing contaminants from automotive parts, but it is important to take appropriate safety precautions to protect the health and safety of operators. By following the guidelines outlined above, operators can minimize the risks associated with laser cleaning and ensure a safe working environment.

#laser #cleaning #automotive #safety #eye protection #fire hazards #exhaust ventilation #electrical safety #training and supervision

frazy kluczowe:

– Laser cleaning safety considerations in automotive applications

– Importance of safety in laser cleaning for automotive parts

– Safety tips for using lasers in automotive cleaning applications

Future trends in laser cleaning technology for the automotive industry

1. Increased automation

One of the key trends in laser cleaning technology for the automotive industry is the increased automation of the process. With advancements in robotics and artificial intelligence, laser cleaning systems are becoming more autonomous, allowing for faster and more precise cleaning of automotive parts.

2. Integration with other technologies

Another trend in laser cleaning technology is the integration with other technologies such as 3D scanning and machine learning. By combining these technologies, laser cleaning systems can adapt to different surfaces and materials, making the process more efficient and effective.

3. Improved safety features

Safety is always a top priority in the automotive industry, and laser cleaning technology is no exception. Future trends in laser cleaning technology include improved safety features such as sensors that can detect obstacles and automatically adjust the cleaning process to avoid accidents.

4. Eco-friendly solutions

As the automotive industry continues to focus on sustainability, laser cleaning technology is expected to become even more eco-friendly. Future trends include the development of laser cleaning systems that use less energy and produce fewer emissions, making them a greener alternative to traditional cleaning methods.

5. Cost-effective solutions

Cost is always a consideration in the automotive industry, and future trends in laser cleaning technology include the development of more cost-effective solutions. By reducing the cost of laser cleaning systems and improving their efficiency, manufacturers can save money while still benefiting from the advantages of laser cleaning technology.

6. Customization options

With advancements in laser technology, future trends in laser cleaning technology for the automotive industry include more customization options. Manufacturers will be able to tailor laser cleaning systems to their specific needs, allowing for greater flexibility and efficiency in the cleaning process.

7. Enhanced performance

Finally, future trends in laser cleaning technology for the automotive industry include enhanced performance capabilities. With improvements in laser technology, cleaning systems will be able to remove even the toughest contaminants from automotive parts, ensuring a high level of cleanliness and quality.

Conclusion

As technology continues to advance, the future of laser cleaning technology in the automotive industry looks promising. With increased automation, integration with other technologies, improved safety features, eco-friendly solutions, cost-effective options, customization capabilities, and enhanced performance, laser cleaning technology is set to revolutionize the way automotive parts are cleaned.

#laser #cleaning #technology #automotive #industry #future #trends #automation #integration #safety #eco-friendly #cost-effective #customization #performance

frazy kluczowe:

– future trends in laser cleaning technology for automotive industry

– laser cleaning technology advancements in automotive industry

– benefits of laser cleaning technology for automotive industry

– laser cleaning technology for automotive industry applications

– future prospects of laser cleaning technology in automotive industry

Impact of laser cleaning on overall product quality

Furthermore, laser cleaning is a non-contact process, which means that there is no physical contact between the cleaning tool and the surface. This eliminates the risk of scratching or damaging delicate materials, ensuring that the product remains in pristine condition. The non-abrasive nature of laser cleaning also prevents wear and tear on the surface, prolonging the lifespan of the product.

Another advantage of laser cleaning is its versatility. It can be used on a wide range of materials, including metals, plastics, ceramics, and composites. This makes it an ideal cleaning solution for industries such as automotive, aerospace, electronics, and medical devices, where cleanliness and precision are paramount.

Overall, the impact of laser cleaning on product quality is undeniable. It ensures a clean, contaminant-free surface that meets the highest standards of quality and performance. By incorporating laser cleaning into their manufacturing processes, companies can improve the overall quality of their products and gain a competitive edge in the market.

- precision cleaning

- non-contact cleaning

- versatile cleaning

- improved product quality

- competitive edge

- cleaning precision

- surface integrity

- product lifespan

- industry applications

- market competitiveness

#laser #cleaning #productquality #precision #noncontact #versatile #competitiveedge

Impact of laser cleaning on overall manufacturing costs

One of the biggest advantages of laser cleaning is its cost-saving potential. Traditional cleaning methods often require the use of harsh chemicals, abrasive materials, and manual labor, all of which can add up to significant costs over time. Laser cleaning, on the other hand, eliminates the need for these costly materials and labor, resulting in substantial savings for manufacturers.

Increased efficiency

Another key benefit of laser cleaning is its ability to improve efficiency in the manufacturing process. Because laser cleaning is a non-contact method, it can be used to clean complex surfaces and hard-to-reach areas that would be difficult or impossible to clean with traditional methods. This increased efficiency can lead to faster production times and higher output, ultimately reducing overall manufacturing costs.

Long-term savings

While the initial investment in laser cleaning technology may be higher than traditional cleaning methods, the long-term savings can far outweigh the upfront costs. Laser cleaning equipment is durable and requires minimal maintenance, resulting in lower operating costs over time. Additionally, the environmental benefits of laser cleaning, such as reduced waste and energy consumption, can lead to further cost savings in the long run.

Conclusion

In conclusion, the impact of laser cleaning on overall manufacturing costs is significant. By reducing the need for costly materials and labor, improving efficiency, and offering long-term savings, laser cleaning technology can help manufacturers streamline their operations and increase profitability. As the manufacturing industry continues to evolve, laser cleaning is poised to play a crucial role in driving down costs and improving competitiveness.

- cost savings

- efficiency

- long-term savings

- laser cleaning technology

- manufacturing industry

- environmental benefits

#laser #cleaning #manufacturing #costs #efficiency #technology #environmental #savings

- The safety considerations of laser cleaning - 17 July 2024

- Applications of laser cleaning in the automotive industry - 12 April 2024